Customer perspective drives change

author: time:2025.06.13 browse:918The ongoing trade war between China and the United States has led to weak demand in the special steel market. Faced with challenges, Gree Group has chosen to practice its internal strength with a "blade inward" attitude, implementing refined upgrades throughout the entire chain from procurement to production and quality inspection, and reshaping the quality defense line with standards that exceed customer expectations.

On site problem 'zero delay': resolving customer anxiety in the workshop

'Quality issues do not stay overnight' is the iron rule of the Grey production line. Any processing abnormalities require on-site coordination with the technical and production departments to develop solutions, and in-depth review through weekly quality meetings. Nowadays, the newly added projectors in the conference room project problem points in high-definition - scratches, tolerance deviations, and other details in a magnified form, allowing operators and quality inspectors to form a "muscle memory" of defects.

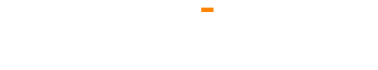

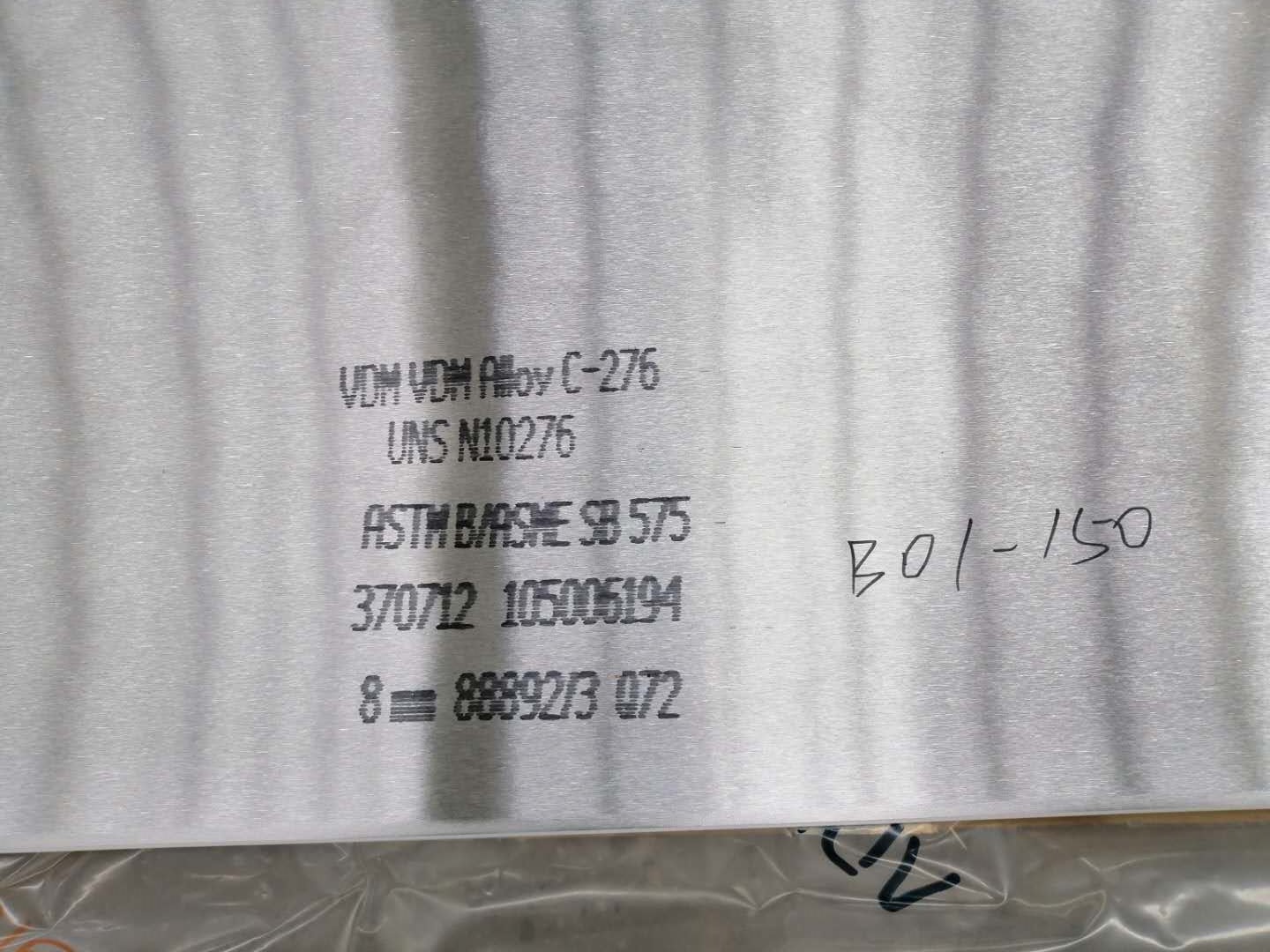

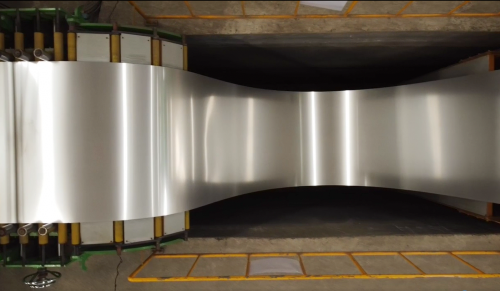

Special industry 'exceeding standards': Explosive disc industry triggers quality revolution

When customers provided feedback that the blasting disc had almost strict requirements for the surface smoothness, Gree immediately initiated a special upgrade: the quality inspection department and production department jointly implemented the "felt protection method" and pasted cushioning materials on all equipment contact surfaces; At the same time, the inspection accuracy will be improved from millimeter level to micrometer level, and the vernier caliper will fully replace the box ruler to ensure that the tolerance is controlled within ± 0.05mm.

When the industry was caught in a price war vortex, Gree chose to "counter the trend and increase investment" in quality. The more picky the customer is, the more we need to think from their perspective - the scratches they are worried about, we use felt to isolate them; the tolerances they are struggling with, we use higher precision tools to verify them. "This is the requirement of the quality inspection department for employees, and also the commitment of Gree to customers. This quality revolution that focuses on details is winning more trust votes for Gray in the cold winter.