Material Solution for Fully Welded Heat Exchanger

author: time:2025.06.04 browse:1018In the field of industrial heat exchange, the selection of materials and the response speed of the supply chain directly determine the performance of equipment and the overall efficiency of the project. As a leading supplier of core materials for all welded heat exchangers, Gree Group provides efficient and accurate material solutions to customers with three major advantages: full specification inventory, flexible zero cutting services, and cross industry resource integration, helping enterprises break through traditional procurement bottlenecks and achieve cost reduction and efficiency improvement.

Full specification inventory, quick response to high-precision demand

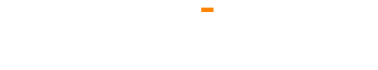

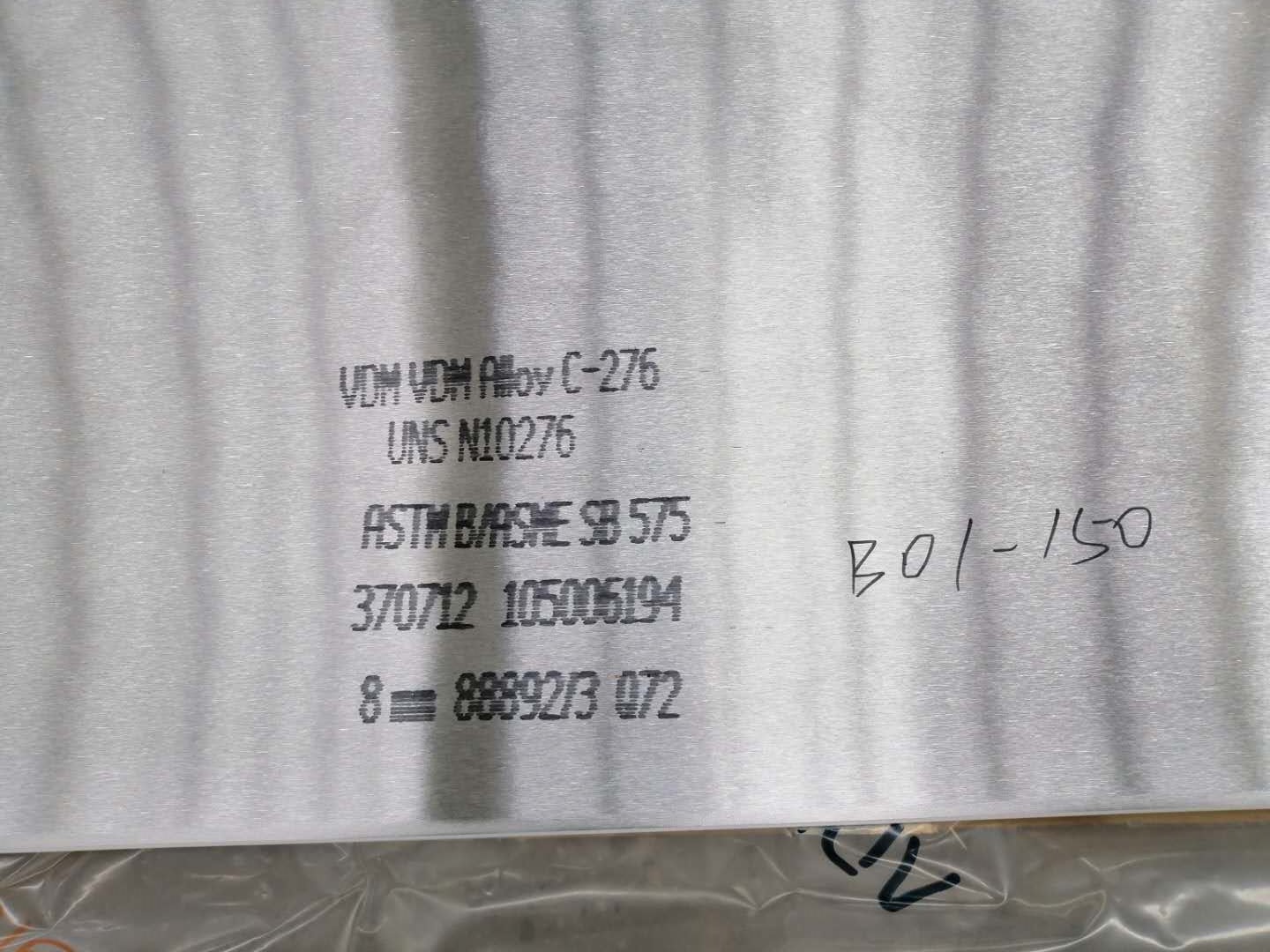

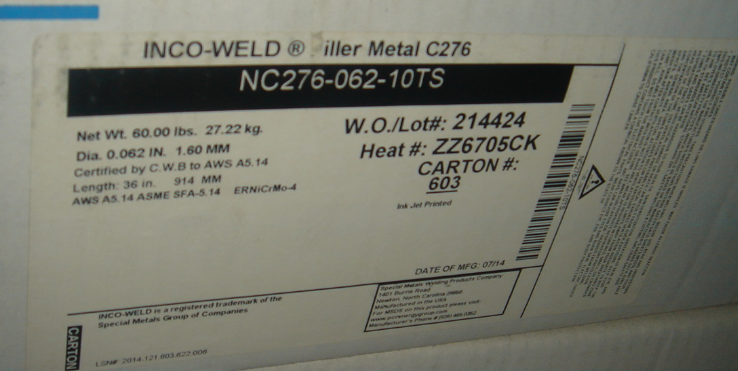

The all welded heat exchanger requires extremely high precision and corrosion resistance of the thin plate material. Relying on a global cooperation network, Gree Group has a year-round reserve of tens of thousands of tons of special alloy spot goods, with precise thickness coverage ranging from 0.8mm to 1.5mm. The inventory covers high-end materials such as titanium plate (TR270C), super stainless steel 254SMO, nickel plate (Ni201), Hastelloy C-276, etc., suitable for harsh working conditions in chemical and new energy industries. Commonly used specifications are available for immediate delivery, significantly reducing the lead time and ensuring efficient progress of customer projects.

Zero Cut Service: Breaking Batch Restrictions and Empowering Flexible Production

In response to small batch needs such as R&D sampling and equipment maintenance, Gree Innovation has launched a single piece zero cutting service, completely solving the pain points of high minimum order quantities and long cycles in traditional steel mills. At the same time, we provide supporting processing such as horizontal cutting, vertical cutting, and pipe fitting production. Customers can directly put them into production, eliminating the need for secondary processing and significantly improving project efficiency. This mode is particularly suitable for small and medium-sized batch procurement needs, providing a solid guarantee for customers' flexible production.

Cross industry collaboration to maximize material utilization

Full welded heat exchanger plates often require non-standard widths (such as 700mm, 800mm), while traditional plates are mostly fixed sizes (such as 1000mm, 1219mm), which can easily cause waste of edge materials. Based on a database of over 3000 industry customers, Gree Group intelligently combines supply solutions by matching the needs of various fields such as corrugated pipe expansion joints and seals, increasing material utilization to over 95% and helping customers significantly reduce procurement costs.

Whether it is the corrosion resistance challenge in the chemical industry or the efficient heat exchange demand in the new energy industry, Gree Group provides customers with one-stop solutions from materials to applications through full category inventory, agile delivery, and customized services. Choosing Gree means choosing the triple guarantee of performance, efficiency, and innovation!