Cracking the anxiety of special materials and leading solutions for corrosive environments

author: time:2025.03.21 browse:1153C-2000、BC-1、 59 alloy

Plate heat exchanger - Gree Group was the first to enter and quickly achieve full specifications of special materials in the industry. For more than 20 years, we have been committed to helping equipment manufacturers solve the problem of material selection in harsh and corrosion-resistant environments.

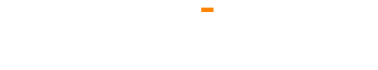

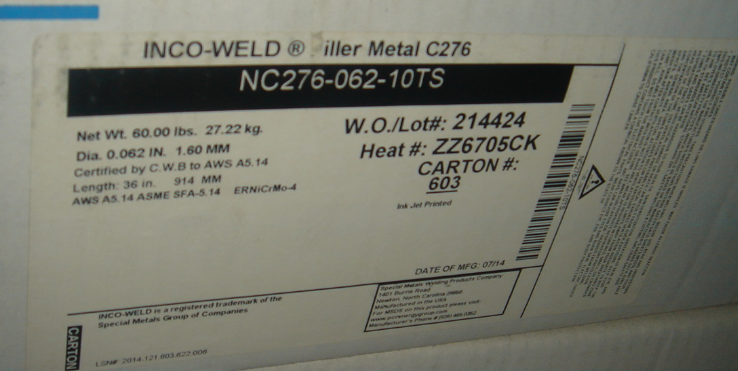

We personally perceive the market demand, listen to feedback from heat exchanger manufacturers, analyze and summarize technological changes, and introduce special material categories from Japanese titanium plates to super austenitic stainless steel S31254 and 904L, and then to Hastelloy C-276. Each iteration of technology stems from the precise capture of "unmet needs". In this process, the more complex the corrosive environment, the more it is necessary to break away from conventional material thinking, which has led to the birth of our "differentiated" business philosophy. Gree Group has successively introduced scarce spot materials such as Hastelloy C-2000, BC-1, and 59 alloys to solve the "special material anxiety" of end users in special working conditions, such as unsuccessful searches, abnormally high prices, and slow delivery times. On this basis, Gree Group implements "minimum order for one piece+72 hour rapid delivery" to solve the industry problems of "special working conditions=ultra long cycle" and "small batch=high cost".

C2000 alloy: It has excellent corrosion resistance, especially good resistance to complex environments containing multiple corrosive media.

BC-1 alloy: It is a nickel based alloy with high strength, good toughness, and excellent high-temperature oxidation resistance. Commonly used in high-temperature, high-pressure, and corrosive working conditions.

59 alloy: generally refers to nickel chromium molybdenum alloy, which has excellent corrosion resistance and oxidation resistance.