Inventory year-end inventory report

author: time:2025.01.10 browse:12351、 Inventory clearance

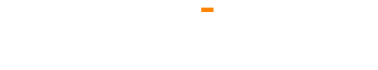

Taking stock of existing goods, we have focused on the quantity changes of the following types of products:

Raw rolls and raw boards: There is a slight downward trend in inventory levels, with specific values showing a decrease of 1.54% in raw rolls and 2.23% in raw boards. This change indicates that Gree's cost refinement management strategy has shown results.

Surplus materials: The number of narrow coils has remained stable overall, and it is worth noting that zero materials have increased for the first time in recent years, with a growth rate of 2.38%. This change not only reflects the trend of increasing small and micro orders, but also indicates that the application areas of special materials are further expanding.

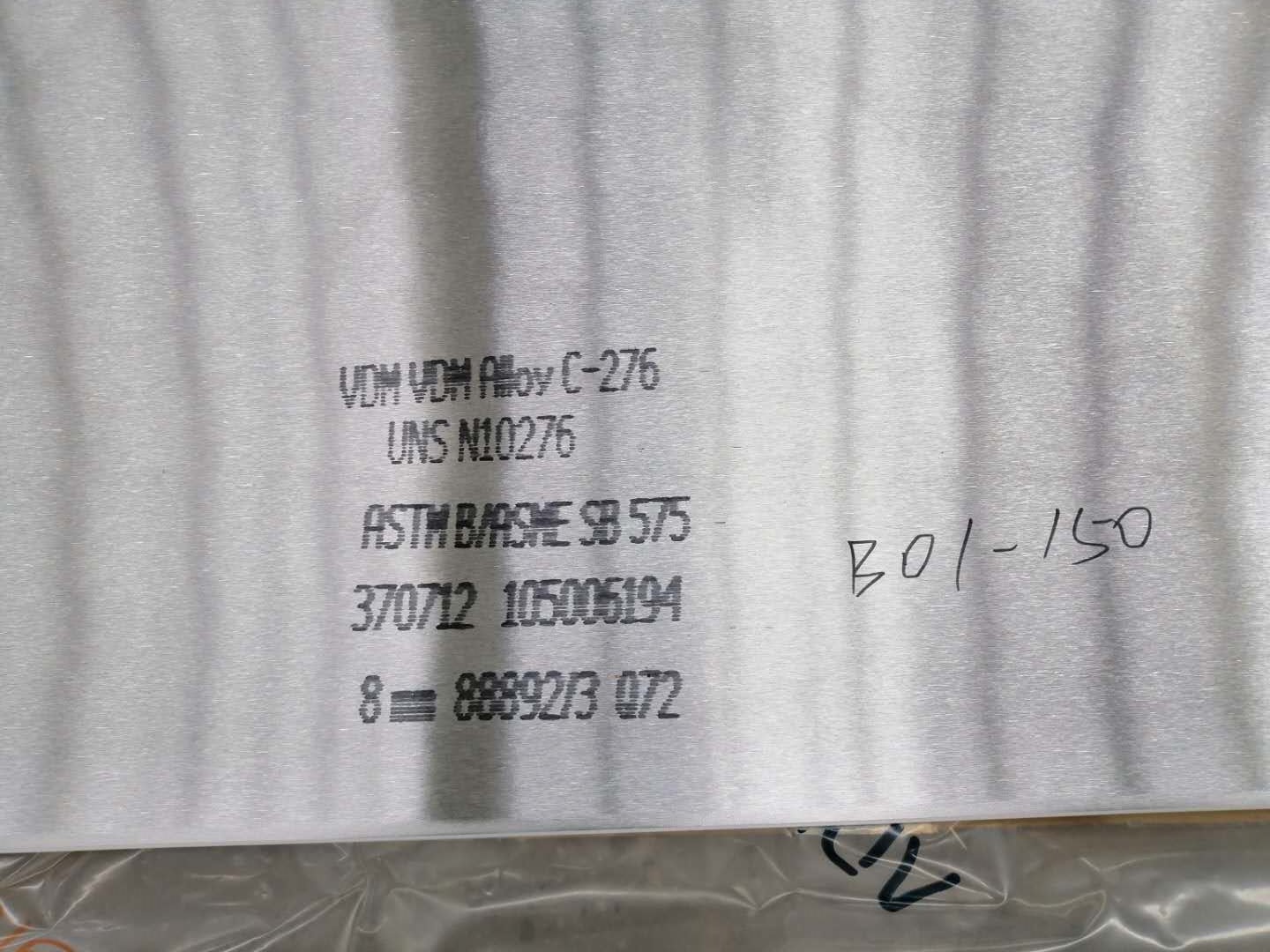

Welding materials: There has been a significant decrease compared to last year, with a decrease of about 5.2%. This significant decrease indicates that Gree accurately grasps customer needs and fully implements the "one-stop" service concept.

2、 List the plan

We have made the following improvements to address the issues identified during the inventory process and how to optimize and effectively manage inventory:

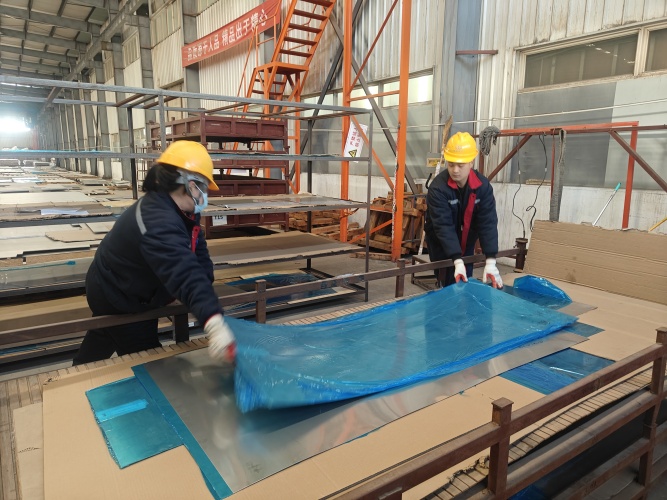

(1). In response to the significant increase in zero material for irregular medium thick plates, we have combined the current stock out rate and plate shape characteristics to carry out reasonable placement and optimized management. This not only effectively utilizes space, but also provides convenience for subsequent outbound work.

(2). In response to the difficulty of zero material management, we cut according to its maximum utilization rate and conventional size, and make clear markings after laminating. This not only facilitates identification, but also reduces the error rate to a certain extent.

(3). In response to the significant difference in turnover rates among different types of welding materials, we have sorted and classified all welding materials. Conduct more detailed statistics and classification of welding materials for each model, and then list them uniformly. This not only frees up more space, but also facilitates management and viewing.